How We Magically Transform Milk

Each of our unique cheeses is handcrafted by our Head Cheesemaker, Paul Sutter, at our cheese factory in Courtenay (a federally inspected CFIA facility).

Read on to find out how young soft cheese matures and why our Cheesemaker has big muscles…

Daily Fresh Milk Delivery

Just like the old days, our daily delivery of fresh cow and water buffalo milk arrives from local farms.

Pasteurizing the Milk

The milk is heated to 72.5C in the pasteurizer to eliminate any pathogens and to make sure it’s safe to consume.Every day, the milk gets tested for its fat content.

From Fat to Vat - Where the Magic Begins

The pasteurized milk is poured into a cheese vat, then our Head Cheesemaker starts making magic. First, we add our own bacterial cultures—different strains for different types of cheese. After about an hour of stirring (yes, our Cheesemaker has big muscles), the microbial enzyme is added and the milk sets for coagulating (thickening).

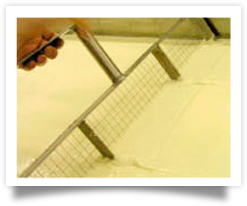

Cutting the Curd

After about 30 minutes of coagulating, the milk has curdled and turned into cheese. But, it’s not ready yet. The Cheesemaker uses a very wide wire knife to cut the curdled milk into small, hazelnut-sized pieces.

Stirring the Curd

The Cheesemaker must now stir the curd, again by hand, carefully for 15 minutes. During this process, the curd shrinks and separates from the whey. (Remember Miss Moffat, eating her curds and whey?)

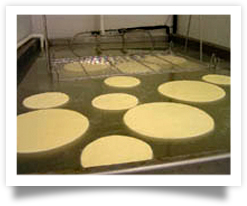

Pouring the Cheese into Moulds

The cheese is poured by hand into the moulds. The pouring has to be done quickly because the curd will keep shrinking.

Stack, Sit & Turn

The filled moulds are then stacked where the cheese will sit for about five hours, during which time the moulds are turned three times.

Salting in Brine

Next, the cheese is soaked in the brine for about two hours to add flavour and to create the right condition for the maturing process.

Maturing

Once removed from the brine, the ‘young’ cheese is placed in the maturing room. Over the next 10 days, the cheese will be turned five times, during which a nice bloomy white mould will grow and cover the surface. The white mould gives the cheese even more flavour with a delicate note of mushroom.

Final Check & Hand Wrapped

Every single cheese is visually checked to make sure it is perfect! Then, each cheese is hand wrapped in special paper so that the cheese can breathe.

Enjoy!

Our cheese is enjoyed in homes and restaurants all over the country!